advantages of rockwell hardness test over brinell hardness test|difference between hrb and hrbw : manufacturing The applied load for the Rockwell hardness test often ranges from 15kgf to 3,000kgf. . Resultado da Rhiana Tokarz. Home; Contacts / DMCA 2021-2024 Nudostar.TVNudostar.TV

{plog:ftitle_list}

Resultado da 409,111. Bad Ice Cream 3 is a third part of the famous maze running games series at Friv. Become the funny ice cream and run around the frozen maze once again. Collect all fruits and survive to complete each level. Break the ice using your special ability. Avoid being touched by enemy creatures, they .

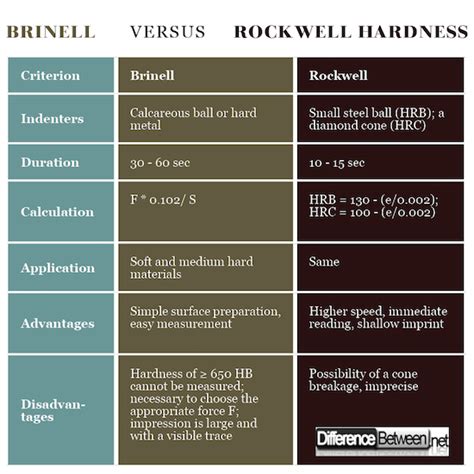

rockwell vs brinell hardness test

In this article, we briefly explained the importance and application, advantages and disadvantages of Rockwell hardness test. We also introduce the Rockwell test with different indenter types, such as diamond cones and carbide balls.Brinell test is better than the Rockwell hardness test because it can measure .The applied load for the Rockwell hardness test often ranges from 15kgf to 3,000kgf. .

Some of the advantages of the Brinell Hardness Test include: Simple surface preparation. Easy measurement of the print diameter. More accurate and precise final measurements compared to Rockwell measurements.

disadvantages of rockwell hardness test

difference between rockwell and brinell

Brinell test is better than the Rockwell hardness test because it can measure the hardness of though material which is not measurable by another test like Rockwell. Brinell test . The Rockwell test offers the advantage of being faster and more convenient than the Brinell test. It is often preferred for materials that have a uniform hardness and are relatively thin. However, it may not be suitable for .Advantages of Brinell and Rockwell Hardness Advantages of Brinell’s method is the simple surface preparation and the easy measurement of the print diameter. Rockwell method is .

The Rockwell test is the less destructive alternative to the Brinell test because it uses a smaller indenter. It is the easiest and least expensive hardness test to administer because it requires very little material prep.

Summary. Key Takeaways. Brinell vs Rockwell Hardness. Comparison Table. What is Brinell Hardness? What is Rockwell Hardness? Main Differences Between Brinell and Rockwell Hardness. Brinell vs Rockwell Hardness.The applied load for the Rockwell hardness test often ranges from 15kgf to 3,000kgf. Advantages: This method does not require optical instruments like other hardness testing . Conclusion: In conclusion, Brinell, Rockwell, and Vickers hardness tests are valuable methods for evaluating the hardness of different materials. Each method has its advantages and is suited to specific testing .

The Brinell Test method has many advantages: The hardness of rough samples can be measured which is difficult with other methods. Application of high test load (up to 3,000 Kg) is possible. . Brinell Hardness Test: .In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured.In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test .

paint inspection qualification

The hardness of metals can be tested by 12 different hardness tests and the Brinell Hardness test is the oldest technique to measure the hardness of metals but is widely used. In this blog, we will discuss only Brinell Hardness test methods, including principle and theory, applications, advantages and disadvantages.

Hardness Methods: The Rockwell hardness test measures the depth of penetra-tion of an indenter into a material under a known load. It provides a hardness value based on the depth of penetration. Rockwell Hardness The Brinell hardness test involves indenting a material with a hard sphere under a specific load. Two diameters (x and y Brinell Hardness. Relatively high loads are applied to parts via a tungsten carbide ball in this method. Unlike with Rockwell testing, Brinell tests measure the diameter of the indentation made by the ball, not the depth. A 10mm ball with an applied load of 3,000 kgf is most common for Brinell testing. Brinell tests are ideal for castings and .Advantages and Limitations of the Brinell Hardness Test. Advantages of the Brinell Hardness Tester. 1. Wide Applicability . The King Brinell hardness tester is specifically designed to conduct Brinell hardness tests, offering precise control over load application and indentation measurement. This equipment is often preferred for its ease of . Rockwell hardness test; . To prevent the material from being pushed over the edge of the specimen during testing and therefore pretending a lower hardness value, the center of the indentation should be at least as far from the edge as 2.5 times the diameter of the indentation. . Brinell hardness testing is particularly suitable for thicker .

Hardness testing is a crucial aspect of metallurgy, as it provides valuable insights into a material’s mechanical properties and overall quality. There are various methods available for measuring hardness, each with its own set of advantages and limitations. In this blog, we’ll delve into the Vickers Hardness Test and discuss when it’s best to use this method over .All information about the Rockwell hardness test Test procedure Differentiation between Rockwell & Super Rockwell Table Hardness Discover now . the indentation size is measured in the Brinell, Vickers and Knoop optical test methods. The deeper a defined indenter penetrates at a defined test force into the surface of a workpiece (specimen .

ASTM E10: This standard covers Brinell hardness testing in metallic samples. ASTM E18: This standard includes the various ways that Rockwell hardness can be measured by standard methods, specifically for metallic materials. ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness . Rockwell Hardness Tester. The Rockwell hardness test is distinguished by its efficiency and the minimal damage it imparts on the test specimen. This test measures the depth of penetration of an indenter under a large load compared to the penetration made by a preload. Understanding Hardness Testing Before diving into the Brinell test, it’s essential to understand that different materials and applications require tailored hardness testing methods. These methods include the Vickers, Rockwell, and Brinell tests, each with its unique advantages. Brinell Hardness Test The Brinell Hardness Test involves .

Advantages of Rockwell Hardness Test Typically, the Rockwell test is easy to execute and more precise than other kinds of hardness evaluations. The Rockwell test technique is used on all metals, except when the test would introduce too many surface variations; when indentations would be too large; or where the sample otherwise prohibits its use.

Knowing the best-suited hardness test of the three, Rockwell, Brinell, and Vickers, for your hardness test will require that you understand the determining criteria for employing any hardness test. . Advantages: Brinell tests are most suitable for rough surfaces and materials as the first widely accepted hardness testing method. It utilizes a .

What is Rockwell Hardness? Similar to Brinell hardness, Rockwell hardness is also used to understand what the hardness of material is in numerical terms. This is done through the use of a Rockwell hardness test . This lower cost and swiftness led the Rockwell test to become the most widely employed hardness measurement system – and this remains the case in 2021. Another advantage of Rockwell testing over Brinell hardness .

High Rockwell hardness numbers represent hard materials and low numbers soft materials. d 2 www.wilsoninstruments.com Fundamentals of Rockwell Hardness Testing Like the Brinell, Vickers, Knoop, Scleroscope and Leeb tests - all of which fall in the general category of indentation hardness tests - the Rockwell test is a measure of the resistance .Applications of Rockwell Hardness Test. Quality Control: Commonly applied in industries that require hard materials on parts and other manufactured products. Material Selection: This tool supports the process of identifying materials that will be applicable depending on the hardness needed. Heat Treatment Evaluation: Using the assessment of the hardness of the treated .These approximate relationships between hardness and tensile strength do not apply to nonferrous metals, with the possible exception of certain aluminum alloys. Related: Brinell Hardness Testing Equation. Table A Brinell Hardness to .The Brinell hardness test, with its unique features and capabilities, offers numerous advantages in the field of hardness testing. Below are some key advantages of the Brinell Hardness Test. 1. Wide Applicability. One of the key advantages of the Brinell Hardness Test is its wide applicability across various materials.

A standardized test procedure used to determine the hardenability of steel, the Jominy test (End Quench Test) can be performed using either the Vickers or Rockwell hardness test method. When selecting which to use, you should consider relevant standards, as well as the usual criteria when choosing between different types of hardness test. What are the advantages of Rockwell over Brinell? Rockwell testing is faster and more versatile compared to Brinell. It provides a more precise hardness value and can be used on a wider range of materials. Rockwell testing is also less affected by the surface condition of the material. Is 45 HRC harder than 60 HRC?

Advantages of Brinell Hardness Test. Simple setup and operation – The Brinell Hardness Test is easy to set up and use, making it accessible for various users without the need for extensive training.; Wide material applicability – It works on a variety of materials, including soft metals and alloys, broadening its usability across different industries.This article details the Brinell to Rockwell hardness conversion chart, which explains how the test results of one scale can be translated into another. + 86 755 61301520; [email protected]; . Rockwell hardness testing has several uses in industries like construction, manufacturing, oil and gas, automotive, etc. .

The easy to use hardness testing software supports the operator with single tests, as well as complex test tasks. Hardness testing according to current standards. Our DuraVision series offers a wide load range from 0.3-250 kg or from 3-3,000 kg for test methods including Vickers, Brinell, Rockwell, Knoop, plastics testing and carbon testing. Advantages of Brinell Hardness Testing . Brinell hardness tests offer a variety of advantages that make them a preferred choice. 1. Adaptability to Testing Different Materials. One of the key advantages of the Brinell hardness test is its ability to test a broad range of materials. It is applicable to metals, alloys, and even some non-metals.Hardness is the property of a material that enables it to resist plastic deformation, usually by penetration. However, the term hardness may also refer to resistance to bending, scratching, abrasion or cutting.

difference between hrb and hrbw

8 de jan. de 2024 · No views 1 minute ago. Aprenda a forma correta de criar uma conta de Afiliado na Elephant Bet. Clica no neste link para criar a sua conta de afiliado:.

advantages of rockwell hardness test over brinell hardness test|difference between hrb and hrbw